Roofing sheets are considered to be an essential part of the construction. The reason for using these sheets is they are resistant to harsh weather conditions and have high durability. Roofing sheets will enhance the beauty and change the overlook of your house. If you’re looking for roofing sheets in Chennai, look for aluminum sheets for their excellent stability and quality. But, have you ever wondered what is the process behind those sparkling sheets placed on top of your house?.

In this post, let’s see the process and post-process involved in manufacturing the sheets. The knowledge about the product will surely help you to purchase a better product.

Raw materials:

The foremost step in the process is converting the raw materials into the desired form. Raw materials like galvalume, aluminum, zinc, copper, and stainless steel are used in the process. Theraw materials are purified and melted down to form the metal coil. The metal roofing in Chennai, uses a different combination of raw materials for better resistance according to the environmental condition.

Coatings:

The coil goes into the coil coater where Kynar 500 or Hylar 5000 coating system is applied. The substance is placed on a continuous coating line where it is cleaned and specially treated with paint and baked at a high temperature. At the end of each coating of paint, it is checked for quality assurance. The redundant check is also done before reaching the manufacturing process by quality assurance engineers.

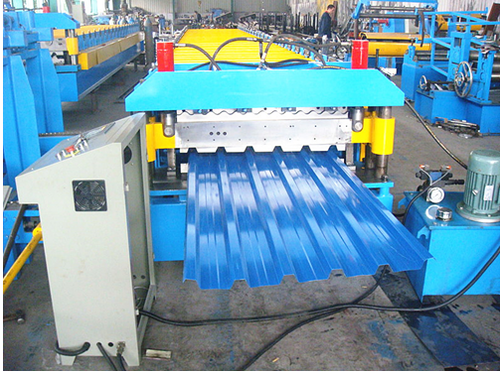

Roller former:

The third step in the process is allowing the metal coil to run into the roller former. A roller former plays a vital role in turning the metal coil into metal sheets and panels. The purpose of running the metal coils into a roller former is to reduce its thickness and achieve the desired grade. The shape and bend in the material are attained by the successive roll of the roller. The width of the sheet is adjusted manually as per the design.

Computer control unit:

The metal roofing in Chennai uses a computer control unit to make changes in speed, control, operation, and panel length. The mill engineers adjust the roller machine and cutting of the panel at a specific length.

Quality check:

The product is immediately inspected for its color, appearance, and quality. Once the sheets pass the quality check they are packed carefully to transit so they can be installed on your roof for a lifetime.

Post-process:

The remnants are collected, bundled, and sold back to the mill to and re-used as metal coils. These scraps are re-used in the manufacturing process continuously for better results.

Despite its outstanding quality and standard, the base of the frame should be strong enough. If the frames are unstable the sheets can’t stand for a longer time. Make sure to get your materials from c purlin manufacturers for a wide variety of roofing accessories with high standards.