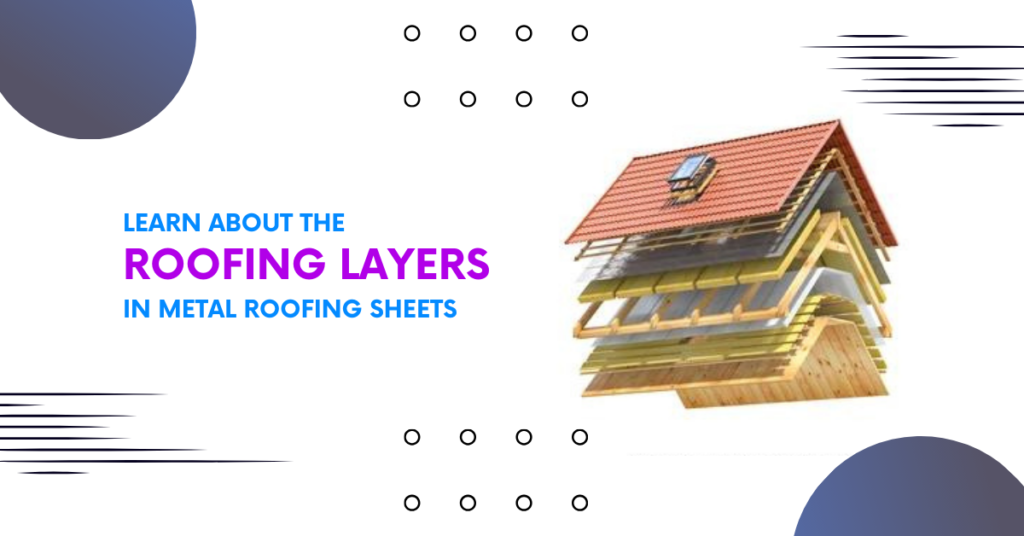

Metal roofing sheets are preferred for various construction roofing purposes due to their extended life span and aesthetics. Also, the primary reason behind these properties is its multiple-layer coating that protects the roofing structure from various elements and enhances its overall performance. This blog will explore the various layers of metal roofing sheets, discussing their composition and functions.

Cold-rolled Steel Sheet:

The foundation of a metal roofing sheet is typically a cold-rolled steel sheet. This steel sheet is produced by rolling steel at low temperatures by the roofing sheet manufacturers in Chennai, enhancing its structural integrity and providing a smooth and even surface for subsequent coatings.

Zinc or Zinc-Aluminum Coating:

The first layer applied to the cold-rolled steel sheet is often a zinc or zinc-aluminum coating. This layer is a sacrificial barrier to protect the underlying steel from corrosion. Zinc plays a critical role at this stage as it blends well with the steel, thereby preventing rusting.

Pre-Treatment:

The roofing sheets undergo pre-treatment procedures such as cleaning, degreasing, and chemical etching before applying top-layer coatings to ensure proper adhesion between the layers. Proper pre-treatment is crucial to ensure the coatings adhere securely to the metal substrate.

Primer Coating:

The primer coating is applied after pre-treatment. It is a bonding layer between the zinc or zinc-aluminum coating and the subsequent layers, enhancing adhesion and providing additional protection against corrosion. The primer also helps create a smooth surface for the top coating.

Top Coating:

The top coating is a critical layer that provides the metal roofing sheet with color, texture, and additional protection. This layer can contain various materials, including silicone-modified polyester (SMP), polyester, polyvinylidene fluoride (PVDF), and others. The choice of top coating material depends on factors like durability, weather resistance, and the desired aesthetic appearance.

Guard Film:

Some metal roofing sheets may apply an optional guard film to the top coating. This film provides temporary protection during transportation, installation, and handling, ensuring the final roof retains its pristine appearance. Once installation is complete, the guard film is typically removed.

Zinc or Zinc-Aluminum Coating (Again):

A second zinc or zinc-aluminum coating is sometimes applied to the back of the metal roofing sheet. This layer further enhances corrosion resistance and protects the entire sheet, including areas that may be exposed during installation.

Pre-Treatment (Again):

The back side of roofing sheets undergoes pre-treatment for perfect adhesion of coatings. Hence, this step ensures consistency and adhesion on both sides of roofing sheets.

Primer Coating (Again):

Primer coating is also applied at the back of roofing sheets to provide additional protection from corrosion and proper adhesion between the roofing layers.

Back Coating:

The back coating is applied at the back side of the roofing sheet as they are subject to weather conditions that cause rusting over time. This additional layer enhances the overall corrosion resistance of the metal roofing sheet.

The various layers in metal roofing sheets play a crucial role in ensuring these roofing materials’ performance, longevity, and aesthetic appeal. Each layer serves a specific function, from protecting against corrosion to providing a visually appealing finish. Approach Crayon Roofing, the best JSW roofing sheet dealer in Chennai, for an excellent choice of metal roofing sheets for various construction projects.