Everyone who builds, contracts, or even builds things as a hobby knows that tiny parts of a structure carry the biggest load. Screws and fasteners may look simple, but they determine whether a roof stays leak-free, whether a joint fails under load, and whether something lasts for years or needs to be fixed in a couple of months.

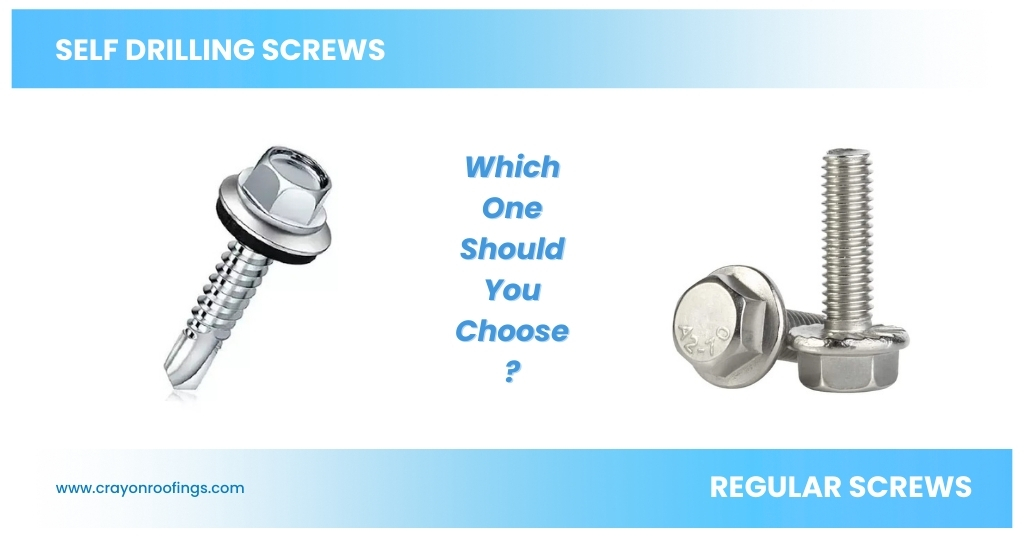

One of the most commonly asked questions is: “Should I use self-drilling screws or just screws?” Well, we know the answer mainly depends on your project, your budget, and your expectations. In this blog, we’ll talk about which one we should use, compare their usages, and explain why Tata Agrico Screws, manufactured by Tata Steel, are the trusted choice for both.

What Are Regular Screws?

Definition and Common Uses

Regular screws are considered the oldest type of fasteners available. They were made specifically to hold together materials like wood, sheet metal, or light structures. When using regular screws, it is often necessary to drill a pilot hole first, and then fasten the screw with a screwdriver or drill.

They are popular for:

- Furniture assembly.

- Wood frames.

- Light-duty applications.

- Regular household projects.

Implications of Regular Screws

A regular screw is somewhat versatile, but it’s not without some trade-offs:

Pre-drilling: This creates an extra step in the process and adds labor time.

Loose: Regular screws may not have the same holding power in a heavy vibration environment.

Time Delay: Because they take longer to install, regular screws aren’t the best fit for big roofing or industrial jobs.

What Are Self-Drilling Screws?

Key Features

Self-drilling screws are advanced fasteners designed with a built-in drill tip for easy installation. In other words, there is no need for a separate pilot hole, as the screw will cut directly into metal or sheet as you drive it in.

Notable features in self-drilling screws include:

- Faster to install

- Superior grip when combined with full thread screws

- Commonly used in roofing and large commercial metal construction

Benefits of Self-Drilling Screws

Time-saving: No need for pilot holes, as you can drive straight into materials without the delay of pre-drilling. Labor costs will reduce.

Durable: We stock corrosion-resistant screws as well, great for outside work.

Leak-proof roofing: When used with washers, they are specially designed so that your roofing is completely leak-proof.

Trusted brand alternatives: If you’re looking for a reliable option, Tata Agrico Screws also provides self-drilling types designed to withstand the challenges of Indian climates.

Self-Drilling Screws vs Regular Screws – A Comparison

Here’s a quick comparison to help you decide:

| Feature | Regular Screws | Self-Drilling Screws |

| Pre-Drilling Required | Yes | No |

| Installation Speed | Slow | Fast |

| Best Use | Light construction, small woodwork projects | Roofing, metal, industrial projects |

| Grip & Strength | Moderate | Strong with full threads |

| Durability | Standard | High with corrosion-resistant coatings |

When Should You Choose Self-Drilling Screws?

Self-tapping screws are perfect for:

- Roof and gutter projects → Quickly install color-coated sheets, JSW, or SAIL roofs.

- Industrial sheds and warehouses → Easily transit through the details and install in record time.

- Connecting metal to metal → Provides for a much stronger clamping force.

- Coastal or humid environments → Rusting is not an issue with Tata Agrico’s screws, which are all corrosion-resistant.

When Should You Choose Regular Screws?

Regular screws are okay for:

- DIY jobs at home → furniture, shelving, or picture frames.

- Woodwork → securing planks, panels, and wood joints.

- Small-scale projects → speed isn’t really a factor.

For basic fastening jobs, they’re a straightforward, budget-friendly, and trustworthy choice.

Why Tata Agrico Screws Are the Better Choice for Both Types

Self-drilling or regular, your brand and quality are most important. Cheaper screws rust, break, or fail. Tata Agrico Screws lead because:

Quality Assurance

- Manufactured at Tata Steel with a strict quality assurance process.

- Every batch is IS certified, individually numbered, and coded for traceability.

Anti-Corrosion

- Multi-coating of zinc and aluminum can prevent corrosion.

- Designed to work in coastal, humid, and industrial environments.

Roofing Applications.

- Tata Agrico roofing screws include EPDM washers, so you have a leak-proof seal.

- Full thread design gives maximum grip on your roofing sheets.

Conclusion – Which One Should You Choose?

Self-drilling or regular? The answer depends on your project.

- Regular screws are fine for small woodwork or household projects.

- Self-drilling screws are better for roofing, industrial sheds, or metal structures.

The right screw always depends on the needs of your project. But whether you go with self-drilling or regular, the most important factor is quality. That’s why builders and contractors consistently rely on Tata Agrico Screws. Known for their strength, anti-rust coating, and IS-certified quality, these fasteners deliver unmatched durability and ensure your structure remains strong and reliable for years.

Are you looking for genuine Tata Agrico Screws in Chennai? Reach out to Crayon Roofings, an authorized Distributor of Tata Agrico Screws, for the best prices, the widest range of screws, and timely deliveries.

FAQs – Self-Drilling Screws vs Regular Screws

Q1: Do self-drilling screws save time?

Yes, they eliminate the need for pilot holes and install faster.

Q2: Are Tata Agrico Screws available in both types?

Yes, Tata Agrico offers both self-drilling screws and regular screws for different applications.

Q3: Which screws are best for roofing sheets?

When it comes to roofing, self-drilling Tata Agrico screws work best because they stop water leaks effectively.

Q4: Do regular screws rust faster?

Yes, unless coated. Tata Agrico corrosion-resistant screws last much longer.

Q5: Can I use self-drilling screws for wood?

These screws work great with metal sheets, but when it comes to wood, regular screws are the smarter choice.